Copyright 2010 automated-devices

automated-devices and the a-d logo are registered trademarks of Stown Industries Ltd.

A "THERMOPLASTIC", by definition, means any material that softens when heated and hardens when cooled. No chemical change takes place when a thermoplastic is heated or cooled. Therefore, the process of softening and hardening can be repeated within the limits imposed by cumulative heat degradation. Because of this, thermoplastics are easily recycled.

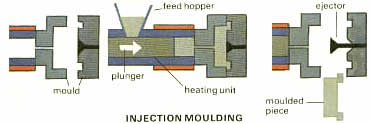

In "THERMOPLASTIC INJECTION MOULDING", pelletized thermoplastic is fed into a heated cylinder. The pellets are heated and softened into a uniform hot mass. The hot mass is then injected, under high pressure, into a closed mould cavity. Once cooled inside the mould, the mould is opened so that the hardened part can be removed. The cycle is then repeated.

The term "CUSTOM INJECTION MOULDING" implies that we mould a broad range of parts with unique set-up and manufacturing procedures. The set-up and manufacturing procedures can be customized in order to conform to each customer's specification. Usually, due to the customization of the product, a custom mould is owned by the customer and maintained by the moulder.

Click on

Wikipedia Link

and

Video Tutorial Link in the main menu to learn even more about injection moulding and how it may suit your project.